Macchine per calzature

e sistemi automatizzati

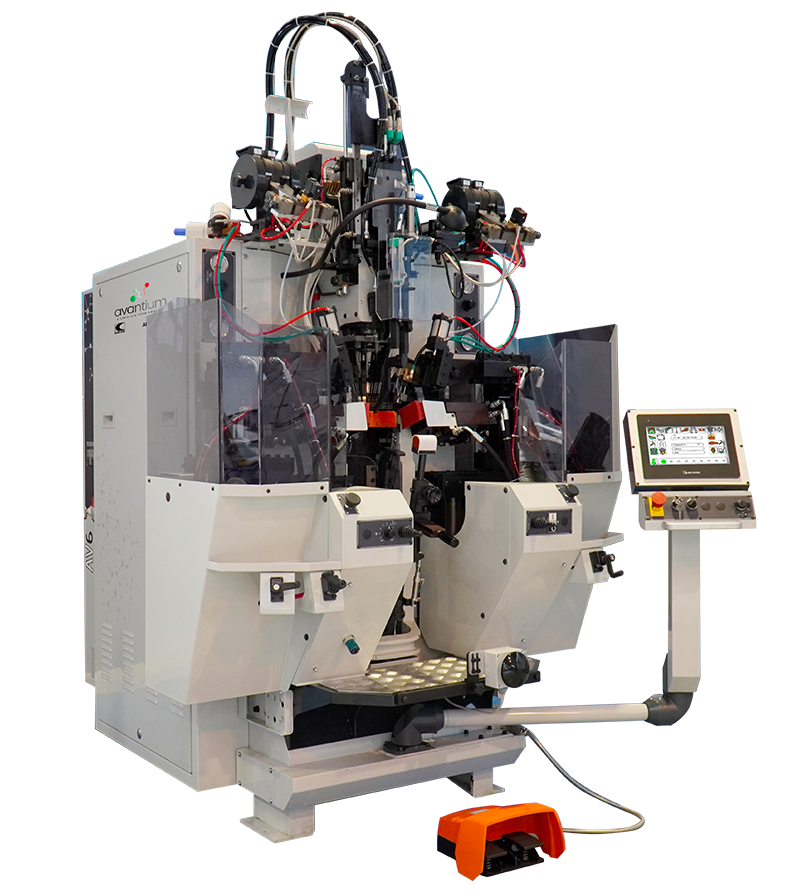

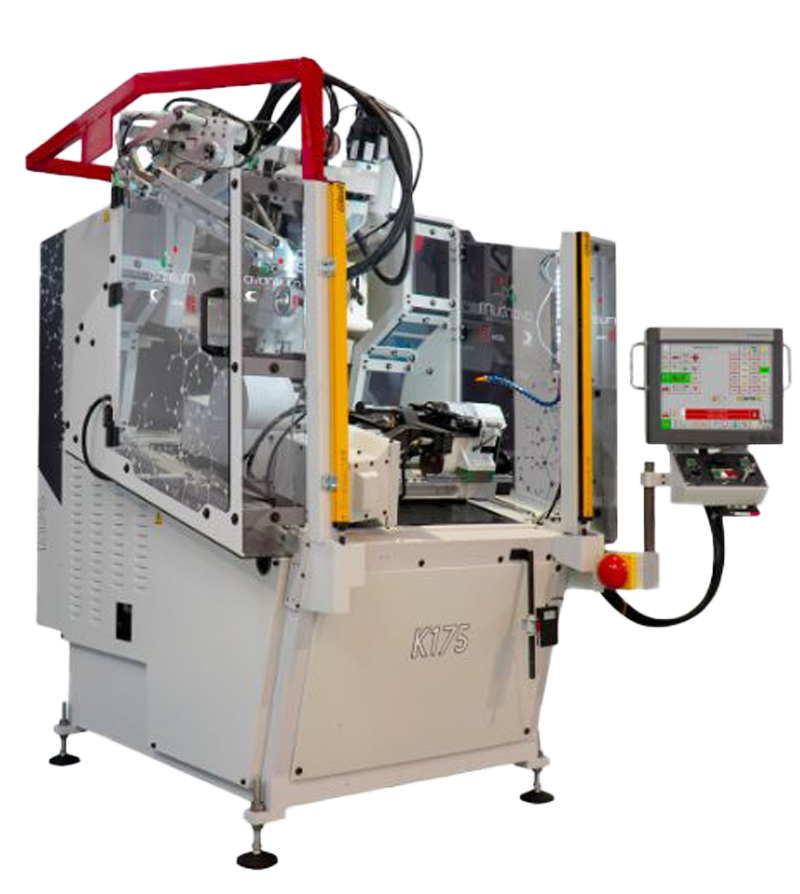

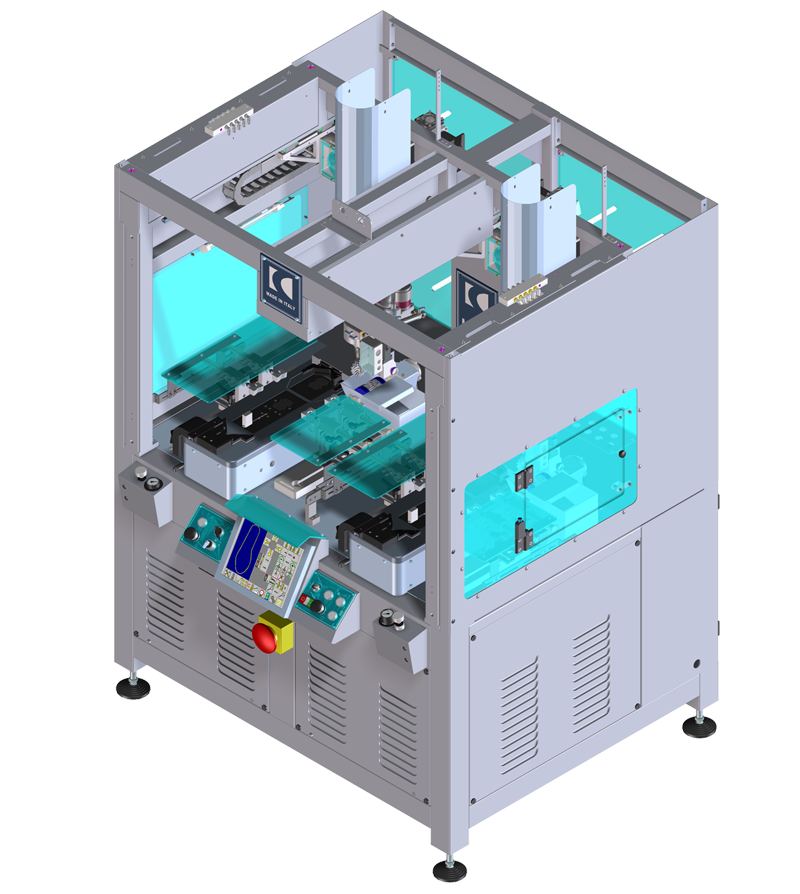

Le nostre macchine

Scopri tutte le macchine di Avantiunm e scarica il catalogo completo

In cosa è specializzata la tua azienda?

Scegli la tipologia di scarpa e scopri le macchine più adatte per produrla

Perché sceglierci?

140 anni di eccellenza nel montaggio calzaturiero

Avantium è marchio nuovo ma con oltre 140 anni di esperienza nel montaggio delle calzature. Nato dalla fusione di due aziende storiche nel settore meccano-calzaturiero, offre la soluzione ideale per le esigenze della moda. Le sue macchine, progettate e costruite in Italia, garantiscono durata e massima affidabilità per i clienti.

Affidabilità, Eccellenza e Impegno Ambientale

La vostra risposta in ogni situazione: Affidabilità, Eccellenza e Impegno. Attraverso una collaborazione efficace con la nostra rete di Dealer, offriamo servizi che garantiscono minimi tempi di fermo, maggiore efficienza e customer service di alta qualità. Il nostro impegno costante si estende alla responsabilità ambientale e alla salute dei lavoratori.

Il cliente prima di tutto

Il nostro impegno è garantire ai nostri clienti i migliori risultati attraverso servizi affidabili e puntuali. Avantium, con una squadra di esperti nel settore, si adatta alle crescenti esigenze dei clienti, sviluppando nuovi prodotti e innovando seguendo da vicino le tendenze di mercato in continua evoluzione